PTFE Fabric: The Ultimate High-Performance Material for Industrial Applications

Update time: 2025-04-12 Views: 678

Description

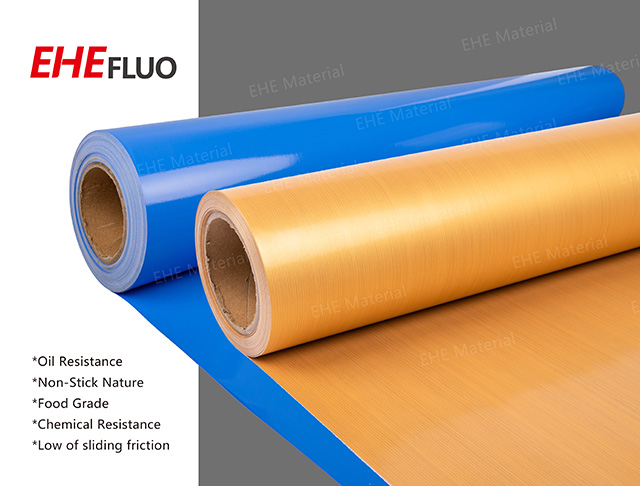

In today’s demanding industrial environments, finding materials that combine durability, versatility, and resistance to extreme conditions is critical. PTFE fabric (Polytetrafluoroethylene fabric) stands out as a top-tier solution for industries worldwide. Whether you need high-temperature resistance, chemical inertness, or exceptional non-stick properties, PTFE-coated fabrics deliver unmatched performance. In this guide, we’ll explore the benefits, applications, and reasons to choose PTFE fabric for your next project.

What is PTFE Fabric?

PTFE fabric is created by coating fiberglass or other high-strength base materials with a layer of PTFE, a synthetic fluoropolymer known for its exceptional thermal and chemical stability. This combination results in a lightweight yet robust material that excels in extreme environments. Key properties include:

Temperature resistance (-200°C to +260°C / -328°F to +500°F)

Non-stick surface (ideal for release applications)

Chemical resistance (resists acids, alkalis, and solvents)

Low friction coefficient

UV and weather resistance

Fire-retardant and self-extinguishing

Top Applications of PTFE Fabric

PTFE-coated fabrics are widely used across industries due to their adaptability and reliability:

Industrial Sealing & Gaskets

Conveyor Belts

Non-stick properties reduce material buildup, improving efficiency in food processing, packaging, and textile manufacturing.

Architectural Membranes

UV-resistant and weatherproof PTFE fabrics are used in stadiums, airports, and tensile structures for long-lasting canopies and roofing.

Release Sheets & Liners

Essential in composite molding, rubber curing, and laminating processes.

Protective Covers & Enclosures

Shields sensitive equipment from heat, corrosion, and debris in aerospace, automotive, and electronics industries.

Why Choose PTFE Fabric Over Alternatives?

Longer Lifespan: PTFE’s inert nature ensures minimal degradation, reducing replacement costs.

Energy Efficiency: Reflective surfaces lower heat absorption, cutting cooling costs in architectural applications.

Compliance: Meets FDA, EU RoHS, and REACH standards for food-safe and eco-friendly use.

Customization: Available in varying weights, thicknesses, and colors to meet specific needs.

How to Source High-Quality PTFE Fabric

When selecting a PTFE fabric supplier, prioritize:

Certifications: ISO 9001, SGS, or industry-specific approvals.

Technical Expertise: Suppliers offering tailored solutions for unique applications.

Global Shipping: Reliable logistics partners to ensure timely delivery.

Competitive Pricing: Balance cost with performance for optimal ROI.

Why Partner With Us?

As a leading manufacturer and exporter of PTFE-coated fabrics, we guarantee:

Premium Materials: Fiberglass, Kevlar, or polyester bases with uniform PTFE coatings.

Custom Sizes: Rolls, sheets, or pre-cut components.

Fast Turnaround: Samples and bulk orders delivered worldwide.

24/7 Support: Technical assistance from concept to installation.

Related Products : PTFE Fabric

Previous: When selecting a heat-insulating and heat-preserving fabric, what kind of Teflon...

Next: What Are Teflon Seamless Belts?