Innovative application and advantages of PTFE belt in food production line

Update time: 2025-08-13 Views: 560

Description

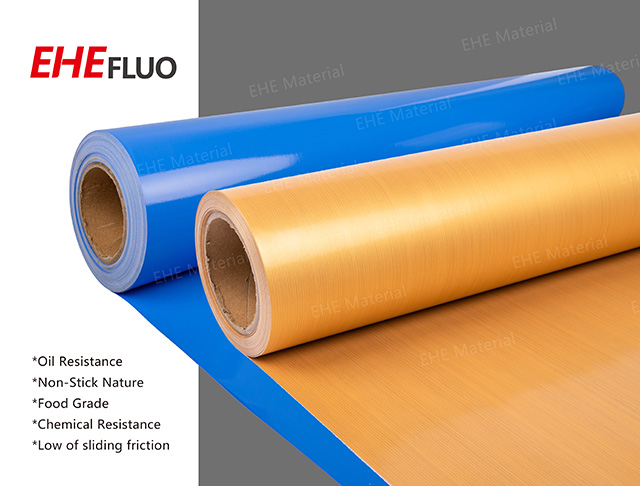

1、Technical characteristics of PTFE belt

1. Excellent temperature resistance: It can work in the temperature range of -70℃to 260℃for a long time, perfectly adapting to the high-temperature baking process in the cake pressing production line

2. Excellent non stick: The surface energy is extremely low, effectively preventing the dough from sticking and ensuring product integrity and aesthetics

3. Chemical stability: resistant to acid and alkali, corrosion-resistant, does not react with food ingredients, meets food grade safety standards

4. High mechanical strength: resistant to tension and wear, with a service life of 3-5 times that of ordinary conveyor belts

5. Compliant with food safety standards: certified by international food contact materials such as FDA and EU

2、Specific application in cake pressing production line

1. Cake forming and conveying process

-Ensure that the dough is evenly conveyed to the rolling station

-Prevent dough adhesion and reduce raw material waste

-Keep the dough surface smooth and improve the quality of the finished product

2. Rolling and Forming Process

-Cooperate with metal pressure rollers to achieve precise thickness control

-High voltage resistance ensures long-term stable operation

-Surface flatness ensures uniform and consistent thickness of the pressed cake

3. Baking process

-Resistant to high temperature baking environment without deformation

-Uniform heat conduction to avoid local overheating or burning

-Not releasing harmful substances to ensure food safety

4. Cooling and packaging section

-Rapid heat dissipation performance accelerates product cooling

-Smooth surface for easy operation of automated packaging equipment

-Reduce product damage rate and lower production costs

3、Selection and usage suggestions

1. Choose surface treatment based on product characteristics:

-Smooth finish: suitable for most pressed cake products

-Matte finish: suitable for special formulas that require increased friction

-Grid pattern: used for products that require special surface textures

2. Thickness selection guide:

-0.13-0.15mm: Lightweight and suitable for small cake presses

-0.18-0.25mm: Universal type, suitable for most cake pressing production

3. Installation and tension adjustment:

-Maintain appropriate tension to avoid being too tight or too loose

-Ensure that the belt running trajectory is centered to prevent deviation

-The joint adopts seamless technology to ensure flatness

Previous: Button Conveyor Belts for Packaging Machines: Enhancing Efficiency in Automated ...

Next: What Are Teflon Seamless Belts?