Button Conveyor Belts for Packaging Machines: Enhancing Efficiency in Automated Production Lines

Update time: 2025-07-29 Views: 709

Description

In the fast-paced world of manufacturing, button conveyor belts for packaging machines have become indispensable for industries ranging from apparel to electronics. These specialized belts ensure precise, damage-free transportation of buttons, fasteners, and small components during high-speed packaging. This article explores the technical features, advantages, and applications of these conveyor systems, providing actionable insights for global buyers.

Key Features of Button Conveyor Belts

1. Precision Engineering for Delicate ComponentsButton conveyor belts are designed with:

Low-Friction Surfaces: Minimizes scratches on buttons (plastic, metal, or resin).

Micro-Groove Patterns: Prevents small parts from slipping or jamming.

Static Dissipation: Anti-static coatings for electronics packaging (e.g., PCB fasteners).

2. Durability in High-Speed Environments

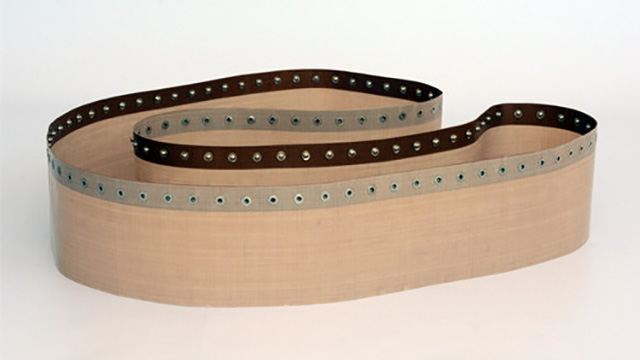

Material: Reinforced with aramid fibers or stainless steel for wear resistance.

Speed Compatibility: Operates at 60–200 meters per minute, matching packaging machine speeds.

Temperature Resistance: Withstands -10°C to 80°C for cold-chain or oven-drying applications.

3. Modular Design for Easy Maintenance

Quick-Release Mechanisms: Simplifies belt replacement during downtime.

Corrosion-Resistant Frames: Aluminum or stainless steel construction for humid environments.

4. Compliance with Industry Standards

FDA Approval: Food-grade belts for packaging buttons in snack bags.

RoHS Compliance: Lead-free materials for electronics manufacturing.

Advantages Over Traditional Conveyor Systems

1. Reduced Product DamageGentle Handling: Eliminates scratches on coated or printed buttons.

Case Study: A clothing manufacturer reduced defect rates by 40% after switching to micro-groove belts.

2. Lower Maintenance Costs

Self-Cleaning Surfaces: Prevents dust accumulation in textile packaging.

Long Lifespan: Aramid-reinforced belts last 3x longer than rubber alternatives.

3. Enhanced Production Efficiency

Zero Downtime: Quick-release design cuts maintenance time by 50%.

Energy Savings: Low-friction materials reduce motor power consumption.

4. Customization Flexibility

Width & Length: Customizable from 100mm to 2000mm.

Add-Ons: Sensors for automatic jam detection, UV-resistant coatings.

Applications Across Industries

1. Apparel & Textile PackagingAutomated Sorting: Transports buttons, zippers, and labels for garment packaging.

Case Study: A jeans manufacturer achieved 99.9% accuracy in rivet placement.

2. Electronics & Automotive

PCB Assembly: Conveys micro-fasteners for smartphone and automotive circuits.

ESD Protection: Anti-static belts prevent electrostatic damage.

3. Food & Beverage

Snack Packaging: Safely transports seasoning packets and toy fasteners in cereal boxes.

Compliance: FDA-approved belts for direct food contact.

4. Medical Device Packaging

Sterile Environments: Cleanroom-compatible belts for surgical kit components.

Traceability: Integrates with RFID systems for batch tracking.

How to Choose the Right Supplier

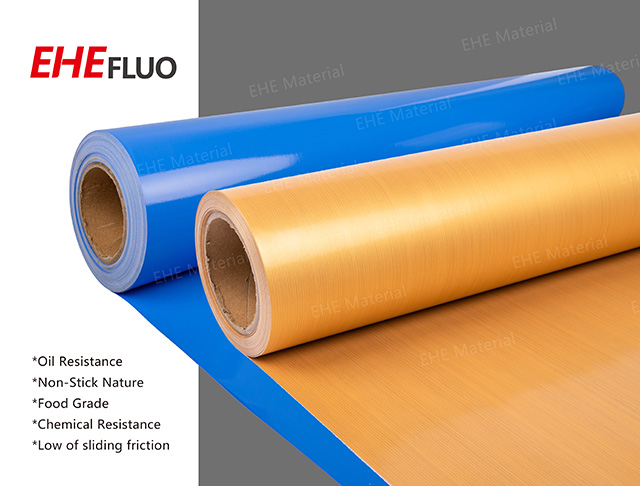

1. Material QualityAramid Fiber Belts: Ideal for high-speed, abrasive environments.

Silicone Coatings: Prevents adhesion in sticky applications (e.g., candy packaging).

2. Certifications

ISO 9001: Ensures consistent manufacturing standards.

CE Marking: Compliance with EU safety directives.

3. Technical Support

On-Site Installation: Vendor-supported setup for complex systems.

Spare Parts Availability: 24/7 access to replacement belts and rollers.

4. Cost-Benefit Analysis

Total Cost of Ownership: Compare upfront costs vs. long-term maintenance savings.

ROI Calculation: A 2,000beltupgrademaysave10,000 annually in reduced defects.

Future Trends in Button Conveyor Technology

1. Smart Sensors & IoT IntegrationReal-Time Monitoring: Detects jams and adjusts speed automatically.

Predictive Maintenance: Alerts before belt wear causes downtime.

2. Sustainable Materials

Recycled Polymers: Eco-friendly belts with 30% post-consumer content.

Biodegradable Options: For single-use packaging applications.

3. 3D Printing Customization

On-Demand Prototypes: Rapidly test belt designs for niche applications.

Button conveyor belts for packaging machines are critical for maintaining efficiency in automated production. By prioritizing precision, durability, and compliance, manufacturers can reduce costs, minimize waste, and stay competitive in global markets.

Previous: PTFE Tape with Release Paper: The Ultimate Solution for Industrial Sealing & Pro...

Next: What Are Teflon Seamless Belts?