Update time: 2025-07-22 Views: 737

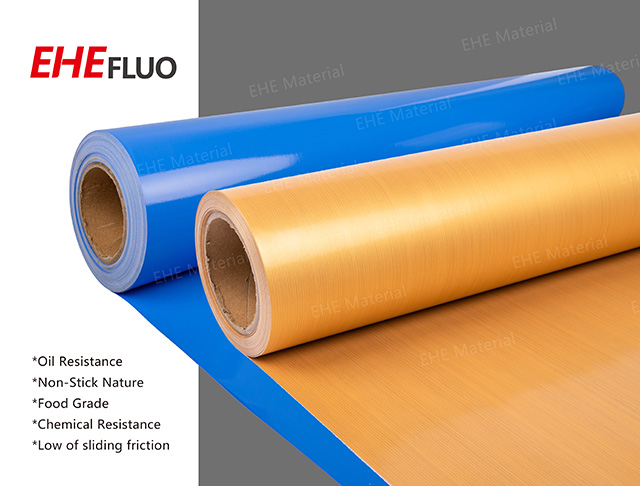

In industries ranging from electronics manufacturing to food processing, PTFE tape with release paper (polytetrafluoroethylene adhesive tape) has emerged as a critical material for sealing, insulation, and protection. This article explores the product's performance, advantages, and applications, providing a comprehensive guide for global buyers seeking reliable industrial solutions.

Product Performance

1. Extreme Chemical Resistance

PTFE tape with release paper is manufactured using polytetrafluoroethylene (PTFE), a material renowned for its exceptional resistance to corrosive substances. It withstands exposure to:

Strong acids (e.g., sulfuric acid, hydrochloric acid)

Alkaline solutions (e.g., sodium hydroxide)

Organic solvents (e.g., acetone, ethanol)

This makes it ideal for sealing applications in chemical processing, electroplating, and semiconductor manufacturing.

2. High-Temperature Stability

The tape operates effectively in temperatures ranging from -200°C to 260°C without melting or degrading. Key applications include:

Aerospace: Sealing high-temperature fuel lines and hydraulic systems.

Electronics: Insulating components in microwave circuits and high-voltage equipment.

3. Low Friction & Non-Stick Properties

With a friction coefficient of 0.04, PTFE tape reduces wear and energy loss in dynamic applications such as:

Bearings: Minimizing friction in mechanical assemblies.

Mold Release: Preventing adhesion in plastic injection molding.

4. Electrical Insulation

The tape’s dielectric strength and resistance to high voltages make it suitable for:

Capacitor media: Enhancing signal integrity in 5G base stations.

Cable Wrapping: Protecting wires in automotive and aerospace systems.

5. Biocompatibility & FDA Compliance

Certified for direct contact with food, pharmaceuticals, and human tissue, the tape is used in:

Medical Devices: Wound dressings, catheter components, and implantable sensors.

Food Packaging: Extending shelf life by sealing bags and containers.

Core Advantages

1. Versatile Material Replacement

Metals: Outperforms stainless steel in corrosive environments, reducing maintenance costs.

Plastics: Surpasses conventional polymers in high-temperature applications.

2. Customization Flexibility

Thickness & Width: Available from 0.13mm to 0.5mm thickness and widths up to 1500mm.

Special Treatments:Conductive Coatings: Anti-static versions for electronics manufacturing.

Adhesive Backing: Pressure-sensitive silicone adhesive for easy application.

3. Certifications & Quality Assurance

FDA: Ensures safety for food and medical use.

ISO 9001: Guarantees consistent manufacturing standards.

RoHS: Complies with environmental regulations.

4. Rapid Delivery & Support

Lead Times: 7–15 days for standard orders, with expedited shipping for urgent requests.

Technical Guidance: Expert advice on material selection and installation.

Applications Across Industries

1. Electronics & Electrical

Flexible Circuits: Base material for high-frequency PCBs in 5G devices.

Thermal Management: Insulating heat sinks in power electronics.

2. Medical & Healthcare

Surgical Instruments: Non-stick coating for blades and forceps.

Diagnostic Devices: Sealing components in blood analysis equipment.

3. Food & Beverage

Packaging Lines: Sealing bags for snacks, frozen foods, and pharmaceuticals.

Baking Equipment: Non-stick lining for oven trays and conveyor belts.

4. Chemical & Environmental

Pipeline Seals: Preventing leaks in corrosive fluid transport.

Waste Treatment: Lining filters in industrial wastewater systems.

5. Automotive & Energy

Battery Packs: Insulating lithium-ion cells in electric vehicles.

Solar Panels: Protecting connections in photovoltaic modules.

Why Choose PTFE Tape with Release Paper?

Durability: Withstands extreme temperatures and chemicals, ensuring long-term reliability.

Efficiency: Reduces friction and energy consumption in mechanical systems.

Safety: FDA-approved for sensitive applications in food and medicine.

Cost-Effectiveness: Lowers maintenance costs by replacing traditional materials.

PTFE tape with release paper is a versatile, high-performance solution for industries demanding precision and reliability. Its unique combination of chemical resistance, thermal stability, and low friction makes it indispensable in modern manufacturing.

Previous: PTFE Coated Fiberglass Fabric Cheap Conveyor Mesh Belt

Next: What Are Teflon Seamless Belts?

Oil resistant PTFE Fabric is used in a wide variety of industrial food processing applications, including contact belt grills, where high productivity is achieved by cooking between upper and lower heated belts. Laminated fabric is the product of choice whenever processing requires high heat and thr...

More Info

Anti-Static Black PTFE Fabric – The EB series is made by combining premium grade fiberglass fabric, PTFE and carbon or graphite to the coating process. These fabrics can be grounded to eliminate static electricity during operation.

More Info

PTFE glass fabric is a high-performance material created by impregnating woven fiberglass fabric with PTFE, resulting in a durable and versatile product. This combination endows the fabric with remarkable attributes, including heat resistance, low friction, excellent electrical properties, and resis...

More Info