Toaster Conveyor Belts: The Ultimate Guide for Industrial Baking Efficiency

Update time: 2025-04-19 Views: 695

Description

In today’s fast-paced food manufacturing sector, toaster conveyor belts are critical components for achieving consistent product quality, maximizing throughput, and minimizing downtime. Whether you operate a large-scale bakery, snack production line, or breakfast food facility, choosing the right conveyor belt for toaster ovens can directly impact your profitability.

This guide explores the key features, benefits, and selection criteria for high-performance toaster conveyor belts, helping global buyers make informed purchasing decisions.

What Are Toaster Conveyor Belts?

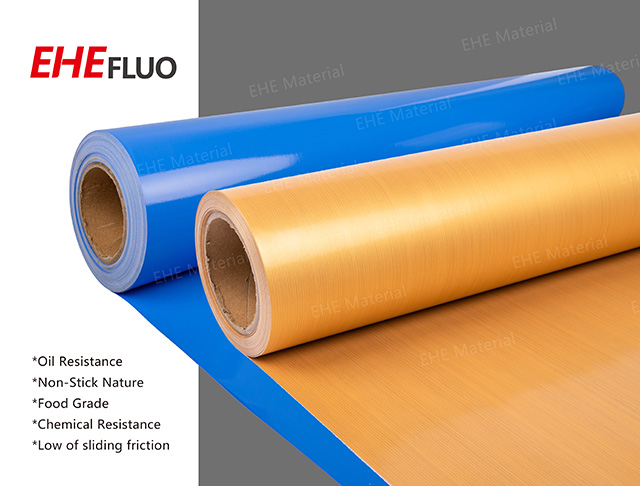

Toaster conveyor belts are specialized heat-resistant belts designed to transport food products through industrial toasting, drying, or baking ovens. Constructed from materials like fiberglass, PTFE (Teflon®), or silicone-coated fabrics, these belts withstand temperatures up to 500°F (260°C) while maintaining flexibility and durability.

Common applications include:

Commercial bread toasters

Breakfast cereal production

Snack food processing (e.g., crackers, waffles, pastries)

Frozen food reheating lines

Top 5 Benefits of High-Quality Toaster Conveyor Belts

Heat Resistance & Stability

Non-Stick Surfaces

PTFE-coated or silicone layers ensure easy release of sticky products (e.g., caramelized snacks), reducing waste and cleanup time.

Extended Lifespan

Durable materials resist abrasion, cuts, and fraying, minimizing replacements and lowering total ownership costs.

Food Safety Compliance

FDA-approved and EU-compliant belts meet global hygiene standards, critical for export-oriented manufacturers.

Customizable Designs

Tailored widths, lengths, and mesh patterns accommodate unique oven configurations or product specifications.

How to Choose the Right Toaster Conveyor Belt Supplier

When sourcing conveyor belts for toaster ovens, prioritize suppliers that offer:

✅ Material Expertise: Look for belts specifically engineered for high-heat environments, not generic conveyor systems.

✅ Certifications: ISO 9001, FDA, or Halal/Kosher compliance for international markets.

✅ Custom Solutions: Ability to modify belt thickness, edge sealing, or tracking guides to fit your machinery.

✅ Technical Support: On-site installation guidance and troubleshooting services.

✅ Global Logistics: Reliable shipping, duty-paid options, and inventory availability for urgent replacements.

Why Partner with EHE Composite Materials for Toaster Conveyor Belts?

At EHE Composite Materials, we specialize in manufacturing high-performance toaster conveyor belts trusted by food producers in 50+ countries. Our advantages include:

Patented Heat-Resistant Materials: Belts endure 2x longer than industry averages under continuous high-heat conditions.

Fast Turnarounds: 7-day production lead time for custom sizes.

Cost Efficiency: Competitive pricing with bulk order discounts.

Sustainability: Eco-friendly materials and recyclable options.

[Insert Call-to-Action Button: Request a Free Sample Today]

Maintenance Tips to Prolong Belt Life

Regular Cleaning: Remove crumbs and grease buildup to prevent fire hazards.

Proper Tensioning: Avoid over-tightening to reduce wear on joints.

Routine Inspections: Check for frayed edges or surface cracks monthly.

Lubrication: Use food-grade lubricants on sprockets to ensure smooth operation.

Industry Applications Spotlight

Bakery Chains: Uniform browning for artisanal breads and bagels.

Snack Manufacturers: Efficient processing of protein bars and granola clusters.

Frozen Food Plants: Reheating conveyor belts for pancakes and waffles.

Conclusion

Investing in premium toaster conveyor belts enhances production efficiency, ensures food safety, and reduces long-term operational costs. Partner with a supplier that combines technical expertise with global reliability to stay ahead in competitive markets.

Previous: PTFE Fabric: The Ultimate High-Performance Material for Industrial Applications

Next: What Are Teflon Seamless Belts?