PTFE Coated Fiberglass: The Ultimate High-Performance Industrial Fabric

Update time: 2025-05-01 Views: 710

Description

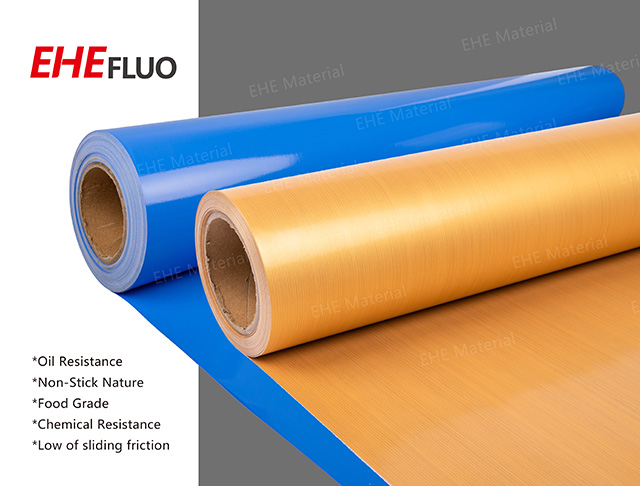

In industries where extreme temperatures, aggressive chemicals, and abrasive wear are the norm, PTFE-coated fiberglass fabric stands as a game-changing solution. Combining the strength of woven fiberglass with the non-stick, corrosion-resistant properties of PTFE (Polytetrafluoroethylene), this material delivers unmatched durability and efficiency. Below, we explore its technical advantages, applications, and why it’s the top choice for OEMs and engineers worldwide.

1. Core Features: Where Engineering Meets Innovation

A. Thermal Mastery: -73°C to 260°C (and Beyond)

Short-Term Spike Resistance: Survives brief exposures up to 315°C (600°F), ideal for thermal shock scenarios.

Low Thermal Conductivity: Acts as an insulator, reducing energy loss in ovens, dryers, and industrial furnaces.

B. Chemical Armor: Corrosion’s Worst Enemy

Inert Surface: PTFE’s fluorine-carbon bonds resist 99% of chemicals, including acids, bases, solvents, and fuels.

UV & Weather Resistance: Unaffected by sunlight, ozone, or moisture, ensuring longevity in outdoor applications.

FDA/EU Compliance: Food-grade variants meet FDA 21 CFR 177.1550 and EU RoHS standards for direct contact with edibles.

C. Mechanical Strength: Toughness Without Compromise

High Tensile Strength: Woven fiberglass base provides 300-900 N/cm tensile strength, 3x stronger than rubber-coated fabrics.

Dimensional Stability: Maintains shape under stress, with minimal elongation (<2%) at break.

Abrasion Resistance: Withstands 10,000+ cycles in Taber Abrasion tests (CS-17 wheel, 1kg load), ideal for conveyor belts.

2. Technical Specifications: Benchmarks That Define Excellence

| Parameter | PTFE-Coated Fiberglass | Industry Baseline | Advantage |

|---|---|---|---|

| Max Operating Temp. | 260°C (500°F) continuous | 180°C (356°F) | +44% higher temp tolerance |

| Coefficient of Friction | 0.04-0.1 (dynamic) | 0.2-0.8 (uncoated materials) | 80% reduction in drag force |

| Dielectric Strength | 20 kV/mm | 5-10 kV/mm (standard fabrics) | 2x electrical insulation |

| Fire Rating | UL94 V-0 (self-extinguishing) | V-2 (flammable) | Zero flame spread, low smoke |

| Weight | 450-1,200 g/m² (customizable) | 800-1,500 g/m² (heavy fabrics) | 30% lighter for energy savings |

A. Food & Pharmaceuticals

Conveyor Belts: Non-stick surfaces for baking, freezing, and packaging lines (e.g., pizza dough, chocolate).

Dryer Fabrics: Even heat distribution in fluid-bed dryers for APIs and supplements.

Release Sheets: Prevents sticking in vacuum forming of medical trays and blister packs.

B. Heavy Industry & Manufacturing

Heat Sealers: Barrier layers in laminating machines for automotive interior components.

Mold Release: Non-stick liners for composites (e.g., wind turbine blades, boat hulls).

Thermal Insulation: Jackets for steam pipes, exhaust systems, and welding curtains.

C. Aerospace & Defense

Radome Liners: Dielectric protection for aircraft radar systems, withstanding 200°C jet exhaust.

Missile Shrouds: Lightweight, heat-resistant covers for missile guidance systems.

Spacecraft Insulation: Multi-layer insulation (MLI) blankets for thermal control in satellites.

D. Environmental & Energy

Flue Gas Filters: PTFE membranes capture 99.9% of particulates in coal-fired power plants.

Geothermal Liners: Resists H₂S corrosion in geothermal wells at 200°C.

Solar Mirrors: Reflective backings for concentrated solar power (CSP) plants.

4. Selection Guide: Tailoring Solutions to Your Needs

A. Temperature & Chemical Exposure

Low-Temp/Mild Chemicals: 0.08mm base fabric with single-layer PTFE (e.g., frozen food packaging).

High-Temp/Aggressive Media: 0.25mm Kevlar®-reinforced fabric with dual-layer PTFE (e.g., chemical processing).

B. Mechanical Load & Flexibility

Light-Duty Applications: 300 N/cm² tensile strength for conveyor belts (e.g., snack food production).

Heavy-Duty Demands: 900 N/cm² tensile strength with anti-static coating for mining conveyors.

C. Compliance & Certifications

Food Safety: Choose FDA/EU-compliant grades for direct food contact.

Flame Retardancy: Opt for UL94 V-0 or FAR 25.853(a) for aerospace/rail.

Electrical Insulation: Select high-dielectric variants (20 kV/mm) for transformers.

D. Customization Options

Coating Thickness: 10-50μm PTFE layers for tailored non-stick performance.

Backing Materials: Silicone, acrylic, or pressure-sensitive adhesives for easy installation.

Color Coding: Red/blue/green fabrics for visual zone identification in factories.

5. Sustainability & Future Trends

A. Eco-Friendly Innovations

Recycled Fiberglass: 30% post-consumer recycled content in base fabrics.

Water-Based PTFE Coatings: Reduce VOC emissions by 70% compared to solvent-based alternatives.

Biodegradable Backings: PLA (polylactic acid) adhesives for temporary applications.

B. Smart Integration

Embedded Sensors: Thermocouples or pressure sensors for real-time performance monitoring.

Self-Healing Coatings: Microcapsules release PTFE resin to repair surface scratches.

AI-Driven Predictive Maintenance: Machine learning optimizes replacement cycles based on usage data.

6. Why Choose Us?

Global Certifications: ISO 9001, AS9100D, and IATF 16949 for automotive/aerospace.

Rapid Prototyping: 3-day turnaround for custom samples (e.g., 0.13mm thickness, anti-static finish).

Lifecycle Support: Free failure analysis and replacement warranties for critical applications.

Ready to revolutionize your thermal management, corrosion protection, or non-stick needs? Request a free material selection audit today—our engineers will analyze your specs and recommend the optimal PTFE-coated fiberglass solution.

Previous: Revolutionizing Food Baking: The Role of PTFE (Teflon) High-Temperature Fabric

Next: What Are Teflon Seamless Belts?