PTFE Coated Fiberglass Fabrics: The Ultimate Guide to High-Performance Materials

Update time: 2025-05-20 Views: 862

Description

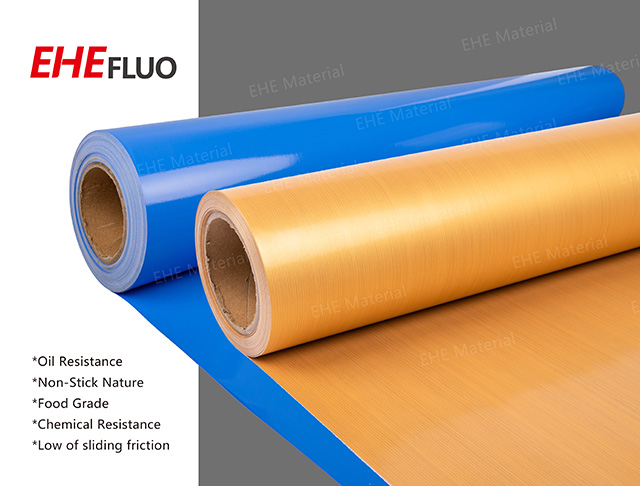

In the world of industrial and commercial applications, durability, heat resistance, and chemical resistance are non-negotiable requirements. Enter PTFE coated fiberglass fabrics—a revolutionary material that combines the strength of fiberglass with the non-stick, heat-resistant properties of PTFE (polytetrafluoroethylene). This dynamic duo creates a fabric that performs exceptionally well in extreme environments, making it a go-to solution for industries ranging from aerospace to food processing. Let’s dive into what makes PTFE-coated fiberglass fabrics so special and why they deserve a spot in your next project.

What Are PTFE Coated Fiberglass Fabrics?

PTFE coated fiberglass fabrics are engineered by applying a layer of PTFE, commonly known as Teflon®, to a woven fiberglass substrate. Fiberglass, made from fine glass fibers, provides exceptional tensile strength and dimensional stability, while PTFE adds a slippery, non-reactive surface. The result? A material that withstands high temperatures, resists chemicals, and remains non-stick even under intense pressure.Key Features and Benefits

1. Unmatched Heat Resistance

PTFE-coated fiberglass fabrics can endure continuous temperatures up to 500°F (260°C) and short-term spikes up to 600°F (315°C). This makes them ideal for applications involving heat sealing, thermal insulation, or exposure to open flames.

2. Superior Chemical Resistance

From acids to solvents, PTFE’s inert nature ensures the fabric remains unaffected by harsh chemicals. This property is critical in industries like chemical processing and wastewater treatment.

3. Non-Stick Surface

The PTFE coating prevents adhesives, resins, and other materials from sticking, simplifying cleanup and reducing downtime. This feature is a game-changer in food packaging, baking mats, and composite molding.

4. Electrical Insulation

With excellent dielectric properties, these fabrics are used in electrical insulation applications, ensuring safety and efficiency in high-voltage environments.

5. Flexibility and Strength

Despite their rigidity at high temperatures, PTFE-coated fiberglass fabrics remain flexible at room temperature, allowing easy handling and installation. The fiberglass base provides tear resistance, ensuring longevity in demanding conditions.

Top Applications of PTFE Coated Fiberglass Fabrics

1. Industrial Conveyor BeltsIn food processing plants, these fabrics act as non-stick belts for baking, freezing, or drying applications. Their heat resistance also makes them perfect for heat-sealing machines in packaging industries.

2. Composite Molding

Aerospace and automotive manufacturers use PTFE-coated fabrics as release sheets during the curing of composites like carbon fiber. The non-stick surface ensures smooth part ejection without residue.

3. Architectural Membranes

Modern architecture uses PTFE-coated fabrics for tensile structures, roofing, and facades. Their durability and UV resistance make them ideal for long-lasting, low-maintenance designs.

4. Chemical Processing

As liners for tanks, pipes, and gaskets, these fabrics prevent corrosion and chemical leaks, ensuring worker safety and compliance with regulations.

5. Electrical Insulation Tapes

Their dielectric strength makes them indispensable for wrapping cables, transformers, and motors in electrical systems.

Why Choose PTFE Coated Fiberglass Fabrics Over Alternatives?

Cost-Effectiveness: While premium-priced, their longevity and low maintenance needs reduce total cost of ownership.Customization: Available in various thicknesses, widths, and finishes (e.g., anti-static, conductive), they cater to niche requirements.

Eco-Friendliness: PTFE is non-toxic, and the fabrics are reusable, aligning with sustainability goals.

How to Select the Right PTFE Coated Fiberglass Fabric

Temperature Requirements: Confirm the maximum operating temperature to avoid premature failure.

Thickness and Flexibility: Thicker fabrics (e.g., 0.13mm–1.5mm) offer more durability, while thinner options suit delicate applications.

Coating Type: One-sided or two-sided PTFE coating? The latter provides enhanced protection for double-sided exposure.

Certifications: Look for FDA, RoHS, or REACH compliance for food or medical use.

Maintenance Tips for Longevity

Regular Cleaning: Use mild detergents and soft brushes to remove residues without damaging the PTFE surface.

Avoid Sharp Objects: Fiberglass is strong but can tear under excessive force.

Store Properly: Keep rolls flat in dry conditions to prevent warping.

Conclusion

PTFE coated fiberglass fabrics are a testament to material engineering innovation. Their ability to withstand extreme conditions while maintaining non-stick and insulating properties makes them indispensable across industries. Whether you’re designing a heat-resistant conveyor belt, a corrosion-resistant lining, or a futuristic architectural marvel, these fabrics deliver reliability and performance.Ready to elevate your project with PTFE coated fiberglass fabrics? Reach out to leading manufacturers today to explore custom solutions tailored to your needs. From prototyping to bulk orders, the possibilities are endless—and the results are built to last.

Previous: Teflon Coated Fiberglass Conveyor Belts: The Ultimate Solution for High-Temperat...

Next: What Are Teflon Seamless Belts?