PTFE Coated Fiberglass Fabrics: The Ultimate Solution for High-Performance Industrial & Architectural Applications

Update time: 2025-06-04 Views: 1272

Description

In the realm of advanced materials, PTFE (Polytetrafluoroethylene) coated fiberglass fabrics stand out as a revolutionary solution that combines exceptional durability, chemical resistance, and thermal stability. Widely used across industries such as aerospace, food processing, construction, and environmental protection, these fabrics offer unmatched performance in extreme conditions. This article explores the technical superiority, applications, and market trends of PTFE-coated fiberglass fabrics, providing insights for global buyers seeking reliable, high-quality materials.

What Are PTFE Coated Fiberglass Fabrics?

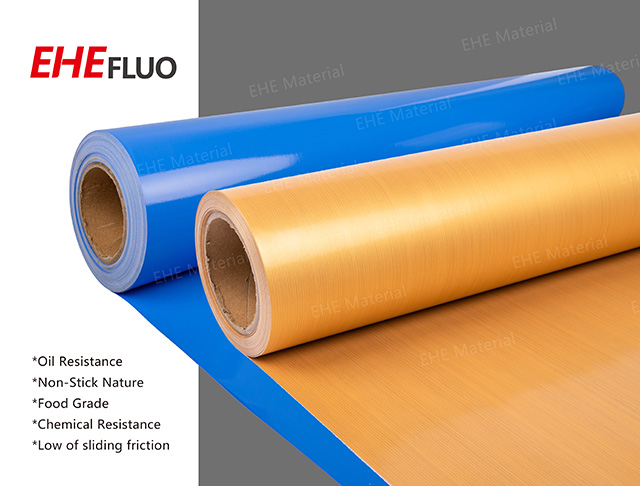

PTFE-coated fiberglass fabrics are composite materials made by impregnating woven fiberglass cloth with PTFE resin. This combination results in a flexible, lightweight yet robust material with a unique set of properties:

Extreme Temperature Resistance:Operates continuously at temperatures ranging from -70°C to 260°C (-94°F to 500°F), withstanding brief exposures up to 300°C (572°F).

Maintains structural integrity and dimensional stability even after prolonged thermal cycling.

Chemical Inertness:

Resistant to acids, alkalis, solvents, and corrosive chemicals, making it ideal for harsh industrial environments.

Non-Stick Surface:

PTFE’s inherent low friction coefficient (0.04–0.10) prevents material adhesion, simplifying cleaning and reducing maintenance.

Dielectric Strength:

Excellent electrical insulator with high dielectric strength, suitable for electronic and electrical applications.

Weatherability:

UV-stable and weather-resistant, with a lifespan exceeding 25 years in outdoor applications.

Fire Resistance:

Classified as A-grade non-combustible material, meeting stringent fire safety standards.

Key Applications Across Industries

The versatility of PTFE-coated fiberglass fabrics drives their adoption in diverse sectors:

1. Industrial Manufacturing

Conveyor Belts: Used in food processing, textiles, and packaging industries for high-temperature resistance and non-stick properties.

Heat Sealing & Release Sheets: Ideal for laminating, thermoforming, and adhesive applications.

Chemical Processing: As liners for reactors, tanks, and pipelines to resist corrosion.

2. Architecture & Construction

Tensile Membranes: Employed in iconic structures like stadiums, airports, and exhibition centers for their lightweight, translucent, and durable properties.

Facade Cladding: Provides weather protection while allowing natural light penetration.

Fire Barriers: Used in high-rise buildings for flame-retardant partitions.

3. Food & Pharmaceuticals

Oven Liners & Grill Mats: Non-stick surfaces for baking and cooking appliances.

Drying Conveyors: Resistant to food acids and oils, ensuring hygiene and ease of cleaning.

Pharmaceutical Packaging: As release films for tablet compression and blister packs.

4. Environmental Protection

Waste Gas Treatment: Used in desulfurization and denitrification systems for power plants.

Corrosion-Resistant Liners: For chemical storage and pollution control equipment.

5. Aerospace & Defense

Thermal Insulation: Protects components from extreme heat in aircraft and spacecraft.

Radomes: Transparent to radio frequencies while shielding antennas from environmental damage.

Market Trends & Global Outlook

The global demand for PTFE-coated fiberglass fabrics is growing steadily, driven by:

Sustainability Initiatives:

Recycling programs for PTFE membranes (e.g., Gore-Tex’s “Recycle Your Gear” campaign) align with global environmental goals.

Technological Advancements:TiO₂-coated variants enhance self-cleaning capabilities and reduce airborne pollutants.

Mesh fabrics improve ventilation and light transmission in building facades.

Regional Shifts:Asia-Pacific: Dominated by China’s manufacturing prowess, accounting for over 30% of global production.

Europe & North America: Focus on premium, certified products for architecture and aerospace.

Industry 4.0 Integration:

Smart fabrics with embedded sensors for real-time performance monitoring in industrial settings.

Why Choose Chinese Manufacturers?

China remains the world’s leading producer of PTFE-coated fiberglass fabrics, offering:

Cost Efficiency: Competitive pricing without compromising quality.

Customization: Tailored solutions for thickness (0.08mm–0.53mm), width (up to 5000mm), and colors (brown, black, white).

Certifications: Compliance with ISO, RoHS, and fire safety standards.

Scalability: Large-scale production capacities to meet bulk orders.

The Future of PTFE-Coated Fiberglass Fabrics

As industries demand lighter, stronger, and smarter materials, PTFE-coated fiberglass fabrics are evolving with:

Nanotechnology Integration: Enhanced surface properties for medical and electronic applications.

Biodegradable Coatings: Addressing PFAS restrictions in Europe.

3D Weaving: Creating complex geometries for aerospace and automotive sectors.

Previous: What are the different types of PTFE coated fiberglass fabrics?

Next: What Are Teflon Seamless Belts?